Blog List

Thiis is Algistors blog, we will post things that insire us and things that we do

If you see something you like, wonder, get in touch with us, perhaps we can help you.

If we feed 47 million tons of CO2 and all nutrients to chlorella how many tons in an optimal case of dry algae could I produce

If you feed 47 million tons of CO2 to chlorella, we can calculate the potential biomass production in an optimal case:

Biomass production = CO2 input / CO2 conversion ratio

Biomass production = 47 million tons CO2 / 1.5 tons CO2 per ton of biomass

Calculating the result: Biomass production = 31.33 million tons of dry algae (approx.)

In an optimal scenario, feeding 47 million tons of CO2 to chlorella could potentially yield approximately 31.33 million tons of dry algae biomass. It’s important to note that this estimate assumes ideal conditions and conversion efficiency, which may vary in practical settings. Additionally, specific cultivation techniques and considerations for nutrient availability are necessary to achieve optimal results in algae production.

Now there is an objective to strive versus.

Harnessing the Structural Strength and Flexibility of Chlorella for Advanced Material Design

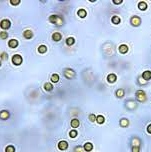

Chlorella’s structural strength, flexibility, and tailorability make it an intriguing contender for advanced material design. Its hierarchical cell wall structure, enhanced tensile strength, and inherent flexibility enable the development of materials with exceptional mechanical properties. From structural engineering to aerospace applications, chlorella-based materials have the potential to revolutionize industries by offering sustainable, high-performance alternatives. Continued research and exploration of chlorella’s unique characteristics will unlock further opportunities for innovative material development.

Read more

Trends on CO2 Capture withMicroalgae: A Bibliometric Analysis

The alarming levels of carbon dioxide (CO2) are an environmental problem that affects the economic growth of the world. CO2 emissions represent penalties and restrictions due to the high carbon footprint. Therefore, sustainable strategies are required to reduce the negative impact that occurs. Among the potential systems for CO2 capture are microalgae.

Bibliometric Analysis for CO2 Capture with Microalgae

The problems caused by contamination by CO2 generate interest worldwide because they are constantly worsening; for this reason, it is pertinent to analyze the trend regarding the capture of CO2 with microalgae through a systematic search in the Scopus scientific review articles. Bibliometric parameters such as the total number of citations, average number of citations per article, categorization of publications with the highest citation, and the process of evolution of the research topic were determined from the Bibliometrix package of the R commander. database with the equation.

Although microalgae have been established as an ecological raw material, the challenges for the commercialization of microalgae systems for capturing CO2 and generating value-added products show the need to redesign production patterns and optimize and integrate processes in order to overcome limitations on economic viability.

Download pdf If you are interested in reading more on the current situation, and which regions lead the development of microalgae, then download the pdf., Today Asia leads the biomedical and cosmetically side, and Europe the Spirulina. Even though the algae market has been established for well over 15 years, it still needs strong manufacturers. With the current global CO2 situation, there’s an upcoming market and advanced materials is most likely the next phase for microalgae.

CO2 to Bioplastics: Beneficial Re-use of Carbon Emissions from Coal-fired Power Plants using Microalgae

Published July 23, 2020

Algistor’s partner is a power plant that runs on multiple feedstocks which is a challenge. A successful large-scale pilot at a coal plant in KY reduces the risk for Algistor since the coal in a coal plant is not a stable feedstock and a lot of the technical challenges that this project faced are the same as Algistor’s.

Bioplastic compounding and material characterization was performed using three feed stocks: whole biomass, lipid-extracted biomass and the proteinaceous residue from full fractionation. Blends were prepared using PLA (polylactic acid)-PBS (polybutylene succinate), PBAT (polybutylene adipate terephthalate) and Nylon resins. In general, the whole and lipid-extracted biomass gave similar results: Nylon fiber and PLA-PBS products showed suitable properties for commercial use, although they did not show significant improvements compared to the neat polymer. Notably, a significant increase in extension at machine peak load was found for 9 fractionated biomass-PBAT tensile bars before breaking in comparison with neat PBAT. This suggests that such a blend could be promising for film applications.

A sustainability assessment of a putative biorefinery system was conducted, including techno-economic and life cycle impact assessments, which were based on a foundational modular engineering system model. The model included sub-process modules developed and validated with experimental and literature data. The model encompassed a system boundary of algae biomass growth through biomass conversion to the sale of products, namely BPFS and fuels (where applicable). Nine different production scenarios were considered, comprising combinations of the three different biomass growth architectures (ORP, PBR, and dual PBR-ORP systems) coupled with three different algae biomass processing pathways (drying only, lipid extraction, and fractionation). The performance of the facility was validated based on experimental systems with modeling work focusing on mass and energy balances of all required sub-processes in the production pathway. Results show that the minimum selling price of the BPFS is within the realm of economic competition with prices as low as $970 USD tonne-1. Additionally, life cycle impact assessment results indicate drastic improvements in the performance of the produced BPFS, with reductions in greenhouse gas emissions ranging between 67 and 116% compared to petroleum-based plastic feedstock. These results indicate that an algae biorefinery focused on BPFS production has the potential to operate both economically and sustainably.

Algae Based Bio-Plastics: Future of Green Economy

Plastic has become one of the most crucial requirements of modern-day living. The continuous reliance on petroleum-based, non-biodegradable plastics has resulted in increased global environmental damage.

Microalgae are well-known for their ease of cultivation, capacity to grow in wastewater, and ability to survive in adverse environments, but producing a marketable product from this biomass has numerous hurdles at each step along the way, from cultivation to market release. Not all species are capable of adapting to a wide range of cultural settings. As a result, the strain chosen for research may not be adapted to the designed conditions, making the cultivation phase challenging. Following cultivation, the harvesting process, which is highly costly, presents the next hurdle. Major research focuses on ways to boost metabolite synthesis, but there is also an urgent need to identify cost-effective harvesting methods. In addition, the biomass and metabolites produced will be insufficient for industrial production. This difficulty can be solved by inducing heterotrophic conditions with an external carbon source, however, there is a high risk of contamination and rapid depletion of fossil fuels. Bioplastic, with remarkably similar properties to petroleum-based plastics, is a promising alternative to overcome these emerging challenges..

With this Algistor’s focus is to become experts in farming algae at an industrial scale, in a sterile and highly automated environment. The algae market misses manufacturing capacity and still has to figure out the farming. Our focus is to move from algae strain innovation to manufacturing development. This is needed not only to hit the needed price points but also volumes.

Italy and Israel bet on GM microalgae to develop edible COVID vaccine

The rush to develop a vaccine for COVID-19 has extended to Italy and Israel, where scientists are using the tools of genetic engineering to develop algae-based edible vaccines against the disease caused by the novel coronavirus.

As I explained in a previous report about work under way in Mexico to develop an edible COVID-19 vaccine delivered through a tomato, plants have numerous advantages — mainly sanitary, storage and transport — over conventional methods for obtaining recombinant vaccines. In the bibliographic search for that report, I observed that microalgae — a type of small, unicellular algae — is another way to obtain recombinant proteins and edible vaccines, with notable results so far.

Besides the problem to develop the best protein strains from microalgae, comes the phase, to find an environment, that’s where Algistor comes in, our focus is to support science, and startups to scale to industrial levels, to be the No 1 farmer of micro algae and bacterias.

Future of Algae A Gene-Edited Vaccine

Algae manufacturing has a very interesting future when micro algae can be turned into the next generation of vaccines.

The mosquito is the most deadly animal on earth. It vectors a plasmodium, a eukaryotic parasite that invades the liver of the host and ultimately attacks red blood cells.

There are

some therapies and preventatives, but a durable vaccine would be a game changer in the Developing World. Dr. Stefan Kappe and his team have developed a vaccine based on the weakened plasmodium parasite. They used CRISPR/Cas9 gene editing to disrupt genes required for life cycle progression, so the vaccinated can receive a vaccination and invoke a strong immunological response against the actual pathogen if encountered.

How to Make Bio-Materials — and Create the Future from Your Kitchen

Learn how to turn algae into natural plastic, and get a life lesson in pursuing what you’re passionate about, from Nike designer Rikke Bonde.

Ever found yourself seeking comfort in banana bread recipes, or fighting off boredom by experimenting with sourdough starter? Well, Nike materials designer Rikke Bonde has a kitchen tutorial for you that’s…a little different.

“When the pandemic started, I saw it as a great opportunity to experiment at home,” she says. Working remotely, Rikke decided to kick-start a side project that had been on her mind — she set up a simple laboratory where she could research, test and develop dozens of recipes for bio-materials: durable plastic- or rubber-like substances made from natural ingredients. “I set up my own rules, like only using items that you have [around the house],” she says of her sustainability-minded approach.

“I think [bio-materials are] the future,” Rikke says. “We have too much [stuff] lying around, and we need to figure out how to reuse it or give it a new purpose. How do we look at the materials that have the least impact on the planet? How can we merge these materials together to make them stronger, or better, or with a new aesthetic?”

A sustainable substitute for palm oil has been created by scientists

A team of scientists led by Nanyang Technological University (NTU), Singapore has developed a method to effectively produce and extract plant-based oils from a type of common microalgae.

As the oils produced from the microalgae are edible and have superior properties to those found in palm oil, the newly discovered method would serve as a healthier and greener alternative to palm oil, according to the research study published in Journal of Applied Phycology.

Compared to palm oil, the oil derived from the microalgae contains more polyunsaturated fatty acids, which can help reduce ‘bad’ cholesterol levels in the blood and lower a person’s risk of heart disease and stroke, the study states. The microalgae-produced oil developed by scientists in Singapore, in collaboration with scientists from the University of Malaya in Malaysia, is also said to contain fewer saturated fatty acids.